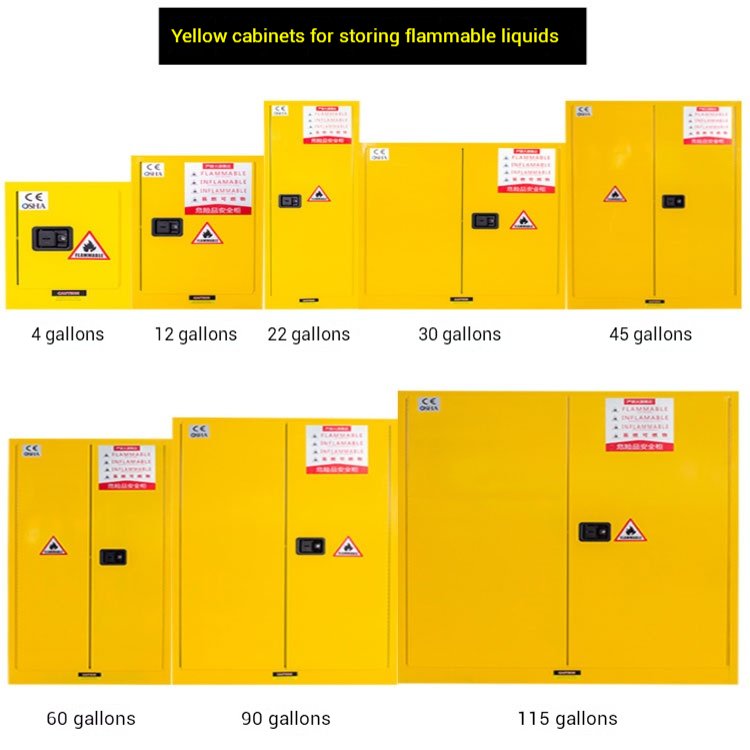

When it comes to storing flammable liquids, choosing the right explosion-proof gallon cabinet isn’t just a matter of convenience—it’s a critical safety decision that can protect your lab, your personnel, and your research. But with sizes ranging from 4 to 115 gallons, how do you determine the perfect fit for your compact workspace? This comprehensive guide will help you make an informed decision that balances safety requirements with space constraints.

Why Size Matters More Than You Think

Selecting the appropriate cabinet size is crucial for several reasons:

- Safety Compliance: Overcrowded cabinets increase spill risks and vapor buildup

- Space Optimization: Small labs can’t afford wasted square footage

- Workflow Efficiency: Easy access improves productivity and reduces accident risks

- Cost Effectiveness: Right-sizing prevents overinvestment while ensuring adequate protection

Understanding Small Lab Storage Needs

Before diving into specific sizes, let’s evaluate what makes a laboratory “small” and how that impacts storage requirements:

Small Lab Characteristics:

- Limited floor space (typically under 500 sq. ft.)

- 1-5 researchers working simultaneously

- Moderate chemical inventory (10-50 gallons of flammables)

- Budget constraints requiring cost-effective solutions

Size Recommendations for Small Chemical Laboratories

Based on extensive industry research and OSHA guidelines, here are the optimal cabinet sizes for different small lab scenarios:

4-Gallon Cabinet: The Micro-Lab Solution

Best For:

- Teaching laboratories and demonstration spaces

- Micro-research facilities with minimal chemical use

- Satellite labs requiring basic solvent storage

Specifications:

- Dimensions: Approximately 18″ H × 15″ W × 12″ D

- Capacity: 2-4 standard 1-gallon containers

- Space Requirement: Fits under most countertops

Pros:

- Minimal footprint

- Budget-friendly

- Easy to move and position

- Perfect for occasional use

Cons:

- Limited storage capacity

- May require frequent restocking

- Not suitable for growing inventories

12-Gallon Cabinet: The Sweet Spot for Most Small Labs

Best For:

- Research laboratories with regular solvent use

- Clinical testing facilities

- Quality control labs

Specifications:

- Dimensions: Approximately 36″ H × 18″ W × 18″ D

- Capacity: 6-8 standard 1-gallon containers

- Space Requirement: Corner placement or against wall

Pros:

- Optimal balance of capacity and size

- Meets most OSHA requirements

- Accommodates various container sizes

- Cost-effective for regular use

Cons:

- Requires dedicated floor space

- May be too large for very compact spaces

22-Gallon Cabinet: The Growing Lab Choice

Best For:

- Expanding research programs

- Small pharmaceutical operations

- Labs with diverse chemical inventories

Specifications:

- Dimensions: Approximately 48″ H × 21″ W × 21″ D

- Capacity: 10-15 standard containers

- Space Requirement: Dedicated storage area

Pros:

- Future-proofs growing needs

- Accommodates larger containers

- Excellent organization capabilities

- Meets stricter compliance requirements

Cons:

- Significant space commitment

- Higher initial investment

- May be oversized for current needs

Quick Reference Sizing Guide

| Lab Type | Chemical Volume | Recommended Size | Key Considerations |

|---|---|---|---|

| Teaching Lab | 2-5 gallons | 4-Gallon | Budget constraints, student access |

| Research Lab | 5-15 gallons | 12-Gallon | Daily use, workflow efficiency |

| Clinical Lab | 8-20 gallons | 12-22 Gallon | Regulatory compliance, multiple users |

| Startup Lab | 10-25 gallons | 22-Gallon | Growth potential, diverse inventory |

Essential Features for Small Lab Cabinets

Regardless of size, your explosion-proof cabinet should include these critical safety features:

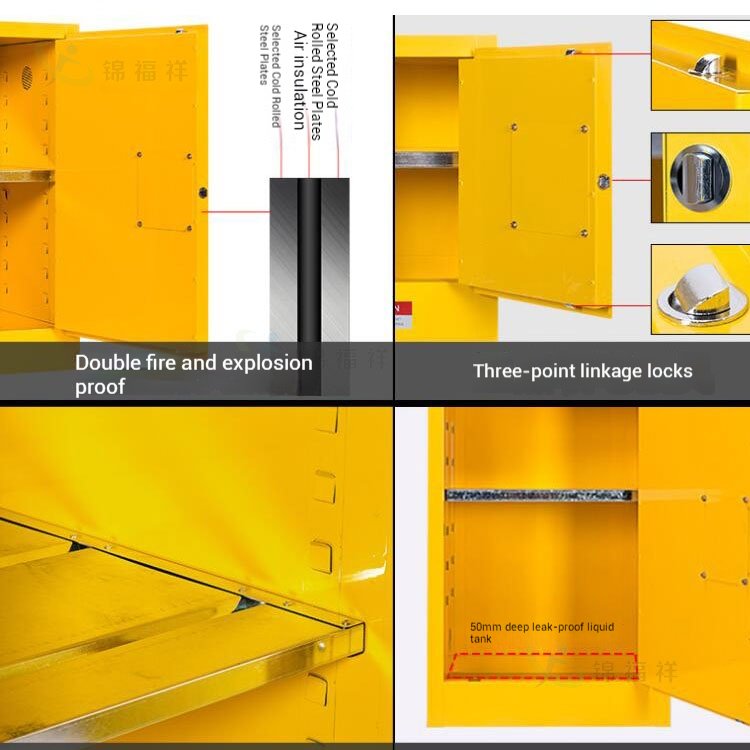

1. Double-Walled Fire Construction

- 1.5-inch air gap between walls

- Fire-resistant steel construction

- 10-minute fire rating minimum

2. Three-Point Locking System

- Secure locking mechanism

- Tamper-resistant design

- Easy emergency access

3. Spill Containment System

- 2-inch deep leak-proof sump

- Corrosion-resistant interior

- Easy cleanup capabilities

4. Ventilation Options

- Flame arrestor vents

- External exhaust compatibility

- Vapor management system

5. Adjustable Shelving

- Customizable storage configuration

- Weight capacity of 350 lbs per shelf

- Easy reorganization capability

Space Planning Considerations

When selecting your cabinet size, consider these practical factors:

Clearance Requirements

- 18 inches of clearance from heat sources

- 36 inches of working space in front

- 12 inches of side clearance for ventilation

Workflow Integration

- Position near workstations for efficiency

- Avoid high-traffic areas

- Ensure easy emergency access

Future Growth Planning

- Allow 20-30% extra capacity for expansion

- Consider modular options for scalability

- Plan for additional safety equipment

Cost-Benefit Analysis

Understanding the total cost of ownership helps justify your investment:

| Cabinet Size | Initial Cost | Annual Maintenance | 5-Year Total Cost | Value Rating |

|---|---|---|---|---|

| 4-Gallon | $800-1,200 | $50-75 | $1,050-1,575 | ★★★☆☆ |

| 12-Gallon | $1,200-1,800 | $75-100 | $1,575-2,300 | ★★★★★ |

| 22-Gallon | $1,800-2,500 | $100-125 | $2,300-3,125 | ★★★★☆ |

Installation and Maintenance Best Practices

Installation Guidelines

- Level placement on solid flooring

- Proper anchoring for taller units

- Professional ventilation hookup

- Clear labeling and signage

Regular Maintenance Schedule

- Monthly: Inspect seals and locks

- Quarterly: Clean interior and check for corrosion

- Annually: Professional safety inspection

- As needed: Replace worn components

Making Your Final Decision

When selecting the right size for your small chemical laboratory, follow this decision-making framework:

Step 1: Assess Current Needs

- Inventory all flammable liquids

- Measure available space

- Evaluate workflow requirements

Step 2: Plan for Growth

- Project future chemical inventory

- Consider expansion plans

- Budget for scalability

Step 3: Verify Compliance

- Check local regulations

- Review OSHA requirements

- Confirm certification standards

Step 4: Compare Options

- Evaluate multiple suppliers

- Request detailed specifications

- Consider total cost of ownership

Step 5: Implement and Monitor

- Professional installation

- Staff training programs

- Regular safety audits

Choosing the right explosion-proof gallon cabinet for your small chemical laboratory is a critical decision that impacts safety, efficiency, and compliance. While the 12-gallon cabinet offers the best balance for most small labs, your specific needs may vary based on chemical inventory, space constraints, and growth plans.

Remember that investing in quality safety equipment is never an expense—it’s an investment in your laboratory’s future. By following this guide and prioritizing both safety and practicality, you’ll create a secure, efficient workspace that supports your research while protecting your team.