In the fast-paced world of warehouse management, heavy-duty shelving isn’t just a storage solution—it’s the backbone of operational efficiency. Whether you’re storing raw materials, finished goods, or bulky equipment, choosing the right shelving system can make or break your workflow. But with so many options on the market, how do you pick the best one for your needs? In this guide, we’ll break down the key factors to consider, ensuring your investment delivers long-term value and safety.

1. Weight Capacity: Don’t Guess—Calculate

The first rule of heavy-duty shelving? Never underestimate weight capacity. A collapsed shelf due to overloading can lead to costly downtime, damaged inventory, and even worker injuries. Start by assessing the heaviest items you plan to store. For example, if you’re housing pallets of metal parts, you’ll need shelves rated for at least 1,000 lbs per level.

Pro Tip: Look for shelves with uniform load ratings (the same capacity across all levels) rather than “total” ratings. This ensures every shelf can handle its share of weight without buckling. Brands like Ridgid or Lyon often provide detailed load charts—use these to match your needs precisely.

2. Material Quality: Steel vs. Other Options

Heavy-duty shelving is only as strong as its material. Steel is the gold standard for warehouses because it’s durable, fire-resistant, and supports high loads. Avoid plastic or wood shelves—they may seem cheaper upfront but will warp, crack, or fail under pressure.

Key Considerations:

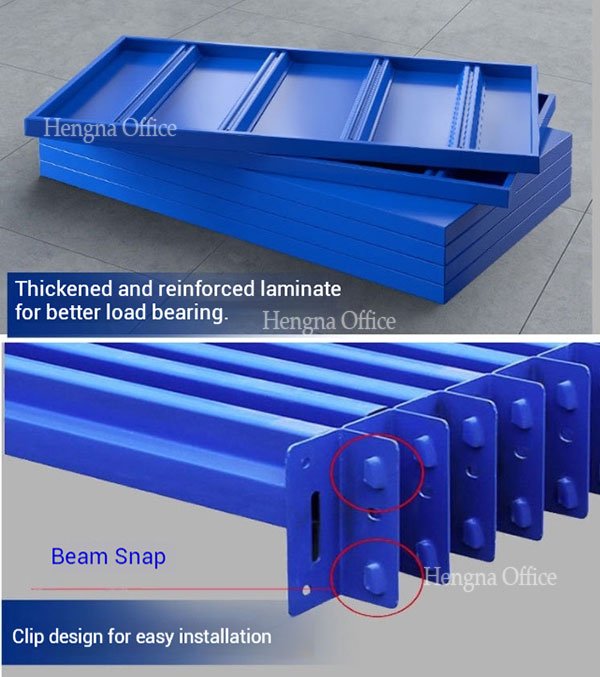

- Gauge Thickness: Thicker steel (lower gauge number, e.g., 14-gauge) means stronger shelves. For industrial use, aim for 14-gauge or thicker.

- Finish: Powder-coated steel resists rust and corrosion, making it ideal for humid or outdoor storage areas. Galvanized steel is another option for extreme environments.

3. Adjustable Shelves: Flexibility for Changing Needs

Warehouses are dynamic—your storage needs today may not match tomorrow’s. Adjustable shelves let you reconfigure space without buying new units. Look for systems with easy-to-move support beams (no tools required!) that slide along pre-drilled holes in the frame. This way, you can accommodate taller boxes one month and shorter bins the next.

Example: If you start storing oversized machinery, simply raise the lower shelves to create more vertical space. Adjustable shelving adapts to your business, not the other way around.

4. Stability: Prevent Tipping and Collapse

A wobbly shelf is a dangerous shelf. Stability comes from two features: robust frames and proper anchoring.

- Frame Design: Look for wide-based frames (at least 18 inches deep) and cross-bracing (diagonal supports) to prevent tipping. Some models include “anti-tip kits” for added security.

- Anchoring: Always bolt your shelving unit to the floor, especially for tall units (over 6 feet). Most manufacturers provide anchor bolts—use them! Even a small earthquake or accidental bump could cause a collapse if shelves aren’t secured.

5. Ease of Assembly: Save Time and Labor Costs

Time is money in warehousing. Complicated assembly leads to delays, frustrated workers, and potential mistakes. Opt for shelving systems with tool-free or minimal-tool assembly. Snap-together components or pre-drilled holes reduce setup time from hours to minutes.

Red Flag: If a product requires welding or specialized tools, skip it. You don’t want to hire a contractor or waste your team’s time on installation.

6. Durability: Long-Term Value Over Short-Term Savings

Cheap shelving may save you money initially, but it will cost you in replacements and repairs. Invest in industrial-grade construction with reinforced joints and thick steel. Look for warranties—reputable brands offer 5–10 year guarantees, which speaks to their confidence in quality.

Case Study: A logistics company switched from flimsy plastic shelves to steel units. Within a year, they reduced replacement costs by 70% and avoided $50,000 in lost productivity from collapsed shelves.

7. Space Optimization: Maximize Every Inch

Warehouses are expensive—every square foot counts. Choose shelving that fits your layout:

- Narrow Aisles: If space is tight, opt for slim-profile units (24–30 inches deep) to leave room for forklifts or picking carts.

- High Ceilings: Use tall shelving (up to 12 feet) to utilize vertical space. Just ensure you have proper lighting and ladders for safe access.

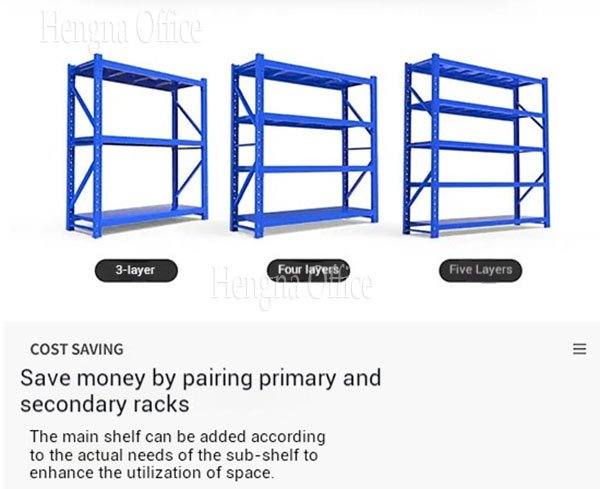

- Modular Designs: Some systems allow you to add or remove sections as your inventory grows. This scalability prevents overbuying and keeps costs manageable.

8. Safety Features: Protect Your Team

Worker safety should be non-negotiable. Look for these features:

- Load Labels: Clear signs indicating maximum weight per shelf. This prevents overloading and reminds staff to follow guidelines.

- Edge Guards: Rounded or padded shelf edges reduce injury risk from bumps or scrapes.

- Non-Slip Surfaces: Rubber mats or textured coatings prevent items from sliding off during movement.

Choosing heavy-duty shelving is an investment in your warehouse’s future. By prioritizing weight capacity, material quality, adjustability, stability, and safety, you’ll build a system that boosts efficiency, reduces risks, and grows with your business. Remember: the cheapest option rarely delivers the best value. Do your research, ask for load tests, and prioritize durability—you won’t regret it.

Ready to upgrade your warehouse? Start by assessing your current needs, then compare options from trusted brands. Your team (and your bottom line) will thank you.