In today’s competitive manufacturing landscape, CNC workshops are constantly seeking ways to maximize productivity while maintaining precision and safety. The unsung hero of many successful machine shops isn’t another expensive piece of equipment—it’s the humble heavy duty tool cart that revolutionizes workflow efficiency. As workshop managers and CNC operators know, the difference between a profitable operation and a struggling one often comes down to how effectively tools and materials are organized and accessed. Let’s explore the five game-changing features that transform heavy duty tool carts from simple storage solutions into essential productivity boosters for your CNC workshop.

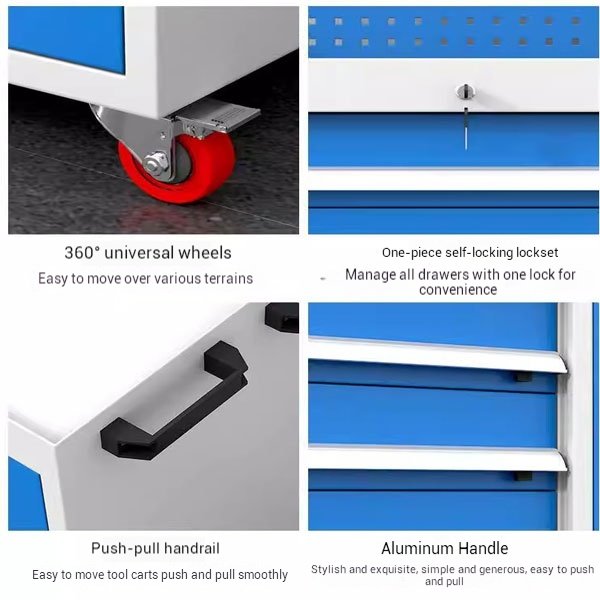

1. 360° Universal Wheels: Unmatched Mobility for Dynamic Workflows

The foundation of any efficient CNC workshop is mobility, and modern heavy duty tool carts deliver this in spades with their 360° universal wheel systems. Unlike traditional fixed-wheel carts that require complete repositioning to change direction, these advanced wheels allow operators to navigate tight spaces between CNC machines, workbenches, and inspection areas with minimal effort. The smooth-rolling mechanism ensures that even when fully loaded with heavy cutting tools, measurement equipment, and raw materials, the cart glides effortlessly across various workshop terrains—from polished concrete to uneven industrial flooring.

Key Benefits of 360° Universal Wheels:

- Zero-radius turning capability for maximum maneuverability

- Reduced physical strain on operators during tool transport

- Time savings of up to 30% compared to traditional carts

- Enhanced safety with smooth, predictable movement patterns

2. One-Lock Security System: Centralized Control for Maximum Efficiency

Imagine being able to secure all your valuable cutting tools, precision instruments, and specialized equipment with a single action. The revolutionary one-lock self-locking system integrated into modern heavy duty tool carts makes this a reality. This centralized security mechanism manages all drawers simultaneously, eliminating the time-consuming process of locking individual compartments and reducing the risk of forgotten tools or unauthorized access.

Security System Advantages:

- 75% faster locking/unlocking process compared to multi-lock systems

- Complete inventory security with single-point control

- Reduced tool loss and improved accountability

- Seamless integration with existing workshop security protocols

3. Ergonomic Push-Pull Handrail Design: Operator Comfort Meets Productivity

The physical demands of daily CNC operations can take a toll on workshop staff, making ergonomic design considerations crucial for long-term productivity. Advanced heavy duty tool carts feature thoughtfully engineered push-pull handrails that optimize operator comfort while maximizing control. These handles are positioned at the ideal height and angle to reduce back strain and shoulder fatigue, even when transporting heavy loads across extended distances.

Ergonomic Design Features:

- Optimized handle height (typically 36-40 inches) for reduced back strain

- Contoured grip design that minimizes hand fatigue

- Balanced weight distribution for effortless pushing and pulling

- Compatibility with both left and right-handed operators

4. Premium Aluminum Handle Construction: Durability Meets Professional Aesthetics

The handle assembly of a heavy duty tool cart serves as both a functional component and a reflection of your workshop’s professional standards. Premium aluminum handles offer the perfect combination of strength, lightweight construction, and corrosion resistance that industrial environments demand. Unlike steel handles that can rust or plastic alternatives that may crack under stress, aluminum maintains its structural integrity while providing a sleek, professional appearance that enhances your workshop’s overall image.

Aluminum Handle Benefits:

- 40% lighter than steel handles with comparable strength

- Natural corrosion resistance for longevity in harsh environments

- Modern aesthetic that complements professional workshop settings

- Temperature-neutral grip comfort in all working conditions

5. Modular Drawer Configuration: Customizable Storage for Every CNC Application

No two CNC workshops operate exactly alike, which is why modular drawer configurations have become essential features in modern heavy duty tool carts. The ability to customize storage compartments means you can organize tools exactly how your workflow demands—from shallow drawers for cutting inserts and measurement tools to deeper compartments for larger equipment and specialized attachments.

Customization Options:

- Variable drawer depths (2-8 inches) for different tool sizes

- Removable dividers for flexible organization

- Weight-rated drawers (up to 100 lbs per drawer) for heavy equipment

- Label-ready surfaces for quick tool identification

Why Heavy Duty Tool Carts Pay for Themselves

Investing in quality heavy duty tool carts isn’t an expense—it’s a strategic investment that delivers measurable returns. Workshops that implement these advanced storage solutions typically report:

- 25-35% reduction in tool retrieval time

- 40% decrease in lost or misplaced equipment

- 50% improvement in overall workshop organization

- 30% increase in operator productivity and satisfaction

Implementation Strategy: Maximizing Your Tool Cart Investment

To fully leverage the efficiency-boosting potential of heavy duty tool carts in your CNC workshop, consider these implementation best practices:

- Conduct a workflow analysis to identify high-traffic areas and tool usage patterns

- Position carts strategically near frequently used CNC machines

- Implement a color-coding system for different tool categories

- Train staff on proper loading techniques and safety procedures

- Schedule regular maintenance to ensure optimal wheel and lock performance

The integration of heavy duty tool carts with these five game-changing features represents more than just an upgrade to your storage solutions—it’s a fundamental transformation of how your CNC workshop operates. By enhancing mobility, security, ergonomics, durability, and customization, these versatile carts become essential productivity partners that help you stay competitive in today’s demanding manufacturing environment.

Don’t let inefficient tool management hold your CNC workshop back from reaching its full potential. The investment in quality heavy duty tool carts pays dividends in productivity, safety, and operator satisfaction that far outweigh the initial cost. Take the first step toward workshop optimization today and experience the difference that intelligent tool organization can make in your daily operations.