In today’s competitive industrial landscape, selecting the right warehouse shelving system is crucial for optimizing storage efficiency, ensuring worker safety, and maximizing operational productivity. Industrial facilities face unique challenges that demand robust, adaptable, and reliable storage solutions. This comprehensive guide will walk you through the essential factors to consider when choosing warehouse shelving that meets your specific industrial needs.

Understanding Your Storage Requirements

Before diving into specific shelving options, it’s essential to assess your facility’s unique storage needs. Consider the following key factors:

- Load Capacity Requirements: Calculate the maximum weight per shelf and total system load your facility needs to handle

- Storage Dimensions: Measure your available space, including ceiling height and floor area

- Inventory Types: Identify whether you’re storing bulky equipment, raw materials, or finished products

- Access Frequency: Determine how often items need to be retrieved and by whom

- Environmental Conditions: Consider temperature, humidity, and potential exposure to chemicals

Key Features to Look for in Industrial Shelving Systems

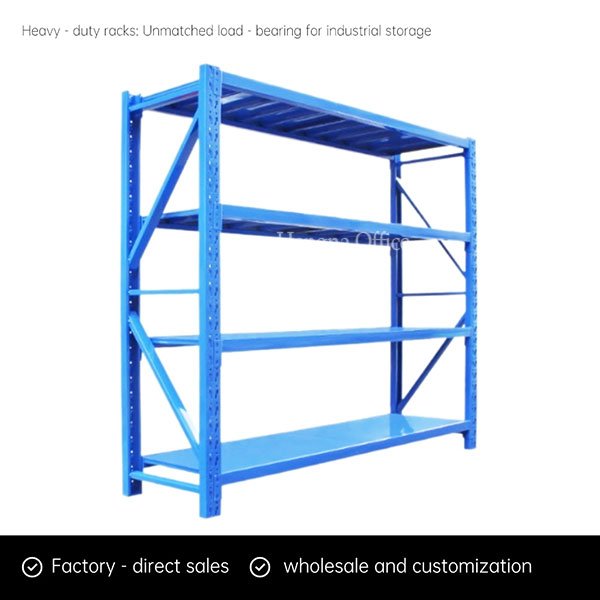

Structural Reinforcement and Durability

When selecting industrial shelving, prioritize systems with advanced reinforcement features that ensure long-term reliability:

- Laminate Reinforcement: Look for shelving units with reinforced laminate layers that distribute weight evenly and prevent surface damage

- Triangle Support Design: Triangular support structures provide superior stability compared to traditional rectangular frames

- Wider Welding Points: Enhanced welding areas create stronger connections between components, reducing the risk of structural failure

- Buckle Design Features: Modern buckle systems add extra security to shelf connections, preventing accidental dislodgement

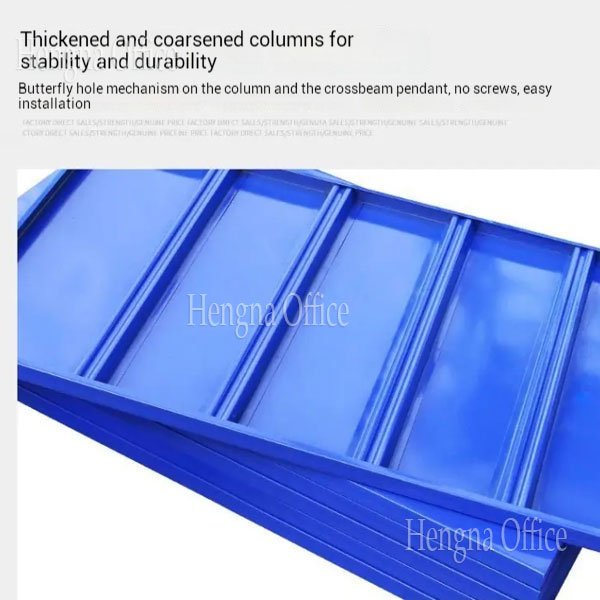

Innovative Assembly Systems

The ease of installation and adjustment can significantly impact your operational efficiency:

- Butterfly Clip Technology: Advanced butterfly clip systems offer exceptional stability and safety while allowing for tool-free adjustments

- Snap Design Mechanisms: Modern butterfly snap designs eliminate the need for screws and wrenches, reducing installation time by up to 60%

- Height Adjustability: Look for systems that allow independent shelf height adjustments to accommodate changing inventory needs

- Tool-Free Assembly: The best systems can be assembled and disassembled quickly without specialized tools or extensive training

Safety and Stability Considerations

Industrial environments demand the highest safety standards. When evaluating shelving systems, prioritize these safety features:

Stability Enhancements

- Progressive Tightening Systems: The more pressure applied to butterfly clips, the more stable the shelving becomes

- Anti-Tip Mechanisms: Built-in features that prevent shelving units from tipping forward when heavily loaded

- Load Distribution Technology: Advanced engineering that evenly distributes weight across all support points

- Safety Locking Mechanisms: Secure locking systems that prevent accidental shelf disengagement

Compliance and Certification

Ensure your chosen shelving system meets or exceeds industry standards:

- OSHA compliance for workplace safety

- ISO certification for manufacturing quality

- Load testing documentation and certifications

- Material safety data sheets for all components

Material Selection and Construction Quality

The choice of materials directly impacts the longevity and performance of your shelving system:

Steel Construction Options

- Cold-Rolled Steel: Offers superior strength and durability for heavy-duty applications

- Galvanized Finishes: Provide excellent corrosion resistance for harsh industrial environments

- Powder Coating: Adds an extra layer of protection against scratches and environmental damage

- Reinforced Joints: Look for systems with reinforced connection points that withstand frequent adjustments

Alternative Materials

- Aluminum Systems: Lightweight options for areas where weight is a concern

- Composite Materials: Modern alternatives that offer strength with reduced weight

- Stainless Steel: Ideal for food-grade or pharmaceutical applications requiring sanitary conditions

Installation and Maintenance Best Practices

Professional Installation Considerations

While modern shelving systems offer tool-free assembly, professional installation may be necessary for:

- Systems exceeding 12 feet in height

- Seismic zone requirements

- Specialized facility configurations

- Multi-level installations

Ongoing Maintenance Requirements

Establish a regular maintenance schedule to ensure optimal performance:

- Monthly inspection of all connection points

- Quarterly load capacity verification

- Annual professional safety audits

- Immediate replacement of damaged components

Cost Analysis and ROI Considerations

When evaluating shelving options, consider the total cost of ownership rather than just initial purchase price:

Initial Investment Factors

- Shelving unit costs

- Installation expenses

- Training requirements

- Additional accessories needed

Long-Term Benefits

- Reduced workplace injuries

- Improved inventory management

- Increased storage capacity

- Enhanced operational efficiency

Making the Final Decision

Selecting the right warehouse shelving system requires careful consideration of multiple factors. By prioritizing safety, durability, and adaptability, you can ensure your investment supports your facility’s growth and operational needs.

Key Takeaways for Industrial Shelving Selection:

- Prioritize systems with advanced reinforcement features like triangle support and wider welding points

- Choose innovative assembly systems with butterfly clip technology for easy adjustments

- Ensure compliance with all relevant safety standards and certifications

- Consider long-term ROI rather than just initial costs

- Plan for future scalability and changing storage needs