When storing flammable liquids, corrosive chemicals, or hazardous materials, 60-gallon explosion-proof safety cabinets aren’t just recommended—they’re essential for workplace safety and regulatory compliance. But with countless suppliers claiming to offer the best products, how do you identify truly reliable partners? This comprehensive guide will walk you through the essential criteria for selecting trustworthy suppliers, helping you protect your facility, employees, and bottom line.

Why Choosing the Right Supplier Matters More Than You Think

The difference between a reputable supplier and an unreliable one can be catastrophic. A quality 60-gallon explosion-proof cabinet serves as your facility’s first line of defense against fire hazards, chemical spills, and regulatory violations. Here’s why supplier selection deserves your utmost attention:

- Safety Protection: Certified cabinets prevent explosions and contain fires, potentially saving lives and preventing millions in property damage

- Regulatory Compliance: OSHA, NFPA, and local authorities require specific safety standards—non-compliance can result in hefty fines or shutdowns

- Long-Term Investment: Quality cabinets last 10+ years, while inferior alternatives may fail within months, costing you more in replacements and downtime

Key Factors to Evaluate When Choosing Your Supplier

1. Product Quality and Construction Standards

Material Specifications to Demand:

- Steel Gauge: Minimum 14-gauge steel construction (12-gauge preferred for heavy-duty applications)

- Finish Quality: Powder-coated finish for corrosion resistance

- Door Mechanism: Self-closing doors with 3-point latching system

- Ventilation: Flame-arresting vents to prevent pressure buildup

- Spill Containment: Built-in sumps to capture accidental leaks

Warranty Expectations: Reputable suppliers offer 5-10 year warranties—anything less suggests confidence issues in their products.

2. Supplier Reputation and Track Record

Due Diligence Checklist:

- [ ] Years in Business: 10+ years indicates stability and experience

- [ ] Customer Reviews: Check Google Reviews, industry forums, and B2B platforms

- [ ] Case Studies: Request examples of similar installations in your industry

- [ ] Industry References: Ask for contacts from companies with similar needs

- [ ] Certification Verification: Confirm all claimed certifications through issuing bodies

3. Customer Support and Service Excellence

Pre-Sale Support Indicators:

- Detailed needs assessment questions about your specific applications

- Willingness to provide technical specifications and test reports

- Transparent pricing with no hidden fees

- Expert guidance on regulatory compliance

After-Sale Service Standards:

- 24/7 technical support availability

- Installation assistance and training

- Prompt replacement of defective parts

- Regular maintenance reminders and guidance

4. Customization and Scalability Options

Flexible Solutions to Look For:

- Adjustable shelving configurations

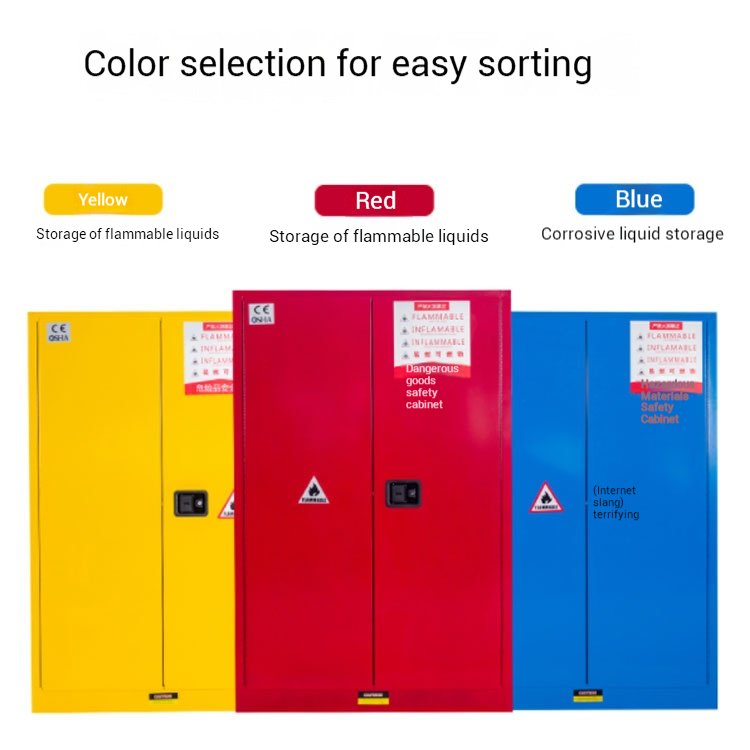

- Specialized coatings for chemical resistance

- Custom sizing for unique space requirements

- Integration with existing safety systems

- Bulk ordering capabilities with volume discounts

Warning Signs: Red Flags to Avoid

🚨 Immediate Deal Breakers:

- Refusal to provide certification documentation

- Vague product descriptions without technical specifications

- Significantly below-market pricing (quality comes at a cost)

- Poor online reviews or no customer feedback available

- Pressure tactics or rush sales tactics

- Limited or no warranty coverage

🚨 Caution Indicators:

- New company with limited track record

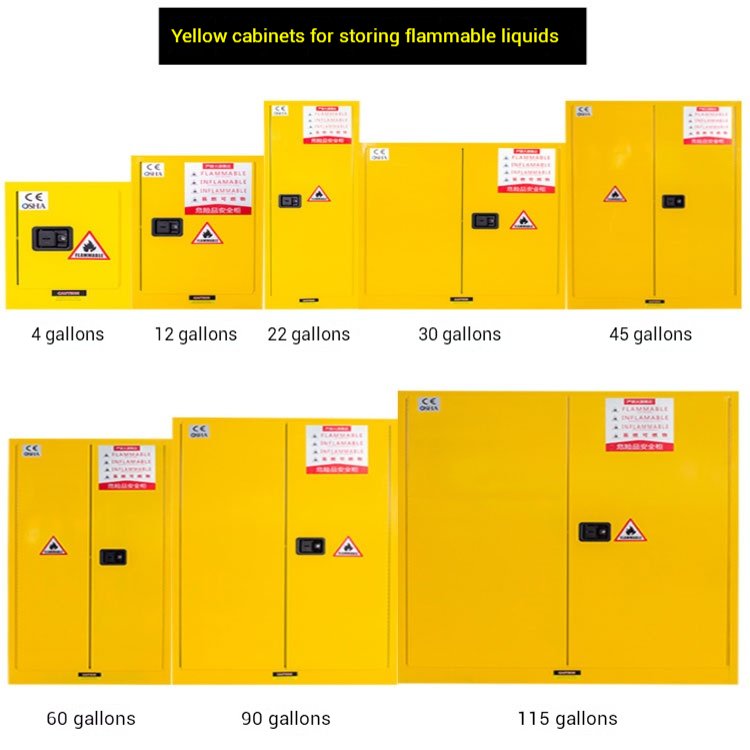

- Limited product line or single-size offerings

- Poor communication or delayed responses

- No physical address or contact information

- Inconsistent information across different platforms

Where to Find Reliable Suppliers

Industry-Approved Sources:

- Trade Associations: National Safety Council, American Industrial Hygiene Association

- Certification Bodies: UL, FM Global, NSF International directories

- Industry Publications: Safety+Health magazine, Industrial Safety & Hygiene News

- Professional Networks: LinkedIn groups, industry conferences, trade shows

- Government Resources: OSHA’s approved vendor lists, EPA compliance directories

Implementation Best Practices

Once you’ve selected your supplier, follow these steps for successful implementation:

- Site Assessment: Ensure proper placement away from heat sources and electrical equipment

- Installation Planning: Verify adequate ventilation and emergency access

- Staff Training: Educate employees on proper usage and emergency procedures

- Regular Inspections: Schedule monthly checks for damage or wear

- Documentation: Maintain records of inspections, maintenance, and certifications

Choosing a trustworthy supplier for 60-gallon explosion-proof safety cabinets is one of the most critical decisions you’ll make for workplace safety. By prioritizing certifications, quality construction, supplier reputation, and comprehensive support, you’re not just buying a cabinet—you’re investing in protection, compliance, and peace of mind.

Remember: The cheapest option rarely offers the best value when safety is at stake. Take the time to thoroughly vet suppliers, demand documentation, and choose partners who demonstrate genuine commitment to your safety goals.

Ready to enhance your facility’s safety? Start by creating your supplier evaluation checklist using the criteria outlined in this guide, and begin the process of finding a partner who will help you maintain the highest safety standards for years to come.